Correction pen is new tool to make cheap diagnostic kits

By neucrad health February 17, 2019

The humble correction pen used to mask typos in printed or written text is all set to assume a new avatar. It could soon become an important component in fabrication of paper-based diagnostic kits.

Paper is becoming popular among experts in miniaturization and micro fluidics because of its ability to transport fluids through capillary action. It is also biodegradable, biocompatible and low cost. Using paper, scientists are developing analytical devices in association with fluorescence, colorimetric and electrochemical detection systems.

Its porosity makes paper easy to load a reagent needed for diagnostic tests. But the reagent needs to be confined to a specific area on the device using certain barriers. Normally such barriers can be fabricated using techniques like photolithography, flexography, plasma treatment, inkjet or screen printing. All these techniques require expert manpower and are time consuming.

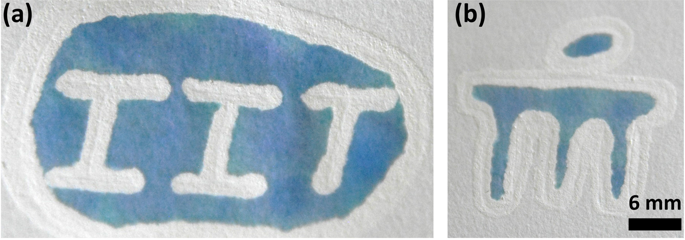

Researchers at the Indian Institute of Technology Kharagpur and Manipal Institute of Technology in Karnataka have now found that merely using a correction pen can help overcome the challenges associated with using paper in diagnostic tests. They have shown it is possible to fabricate paper-based devices by drawing out the confines for reagents with a normal correction pens.

” Paper is becoming popular among experts in miniaturization and micro fluidics because of its ability to transport fluids through capillary action.”

“Even a novice can draw out the margins with a free-hand drawing. The device will work,” said Professor Suman Chakraborty of IIT Kharagpur, who led the research team. The correction pen contains titanium particles. When a line or a circle is drawn on a paper using correction pen, fine particles of titanium form barriers across channels on the paper, forming a confined space within which a reagent can be stored.

The scientists explored the possibility of developing a quantitative assay for blood glucose level – an important blood parameter. They tested 12 blood samples of varying glucose concentrations. Each sample was deposited in three different devices and the average colour intensities were measured. “All the reported data points agreed within 10% of the calibration curve”, researchers said.

“Our study may pave the way for developing a frugal titanium-based composites or inks for constructing paper-based device for bio-sensing applications compatible with the requirements of the economically deprived community at large, resulting in medical tests to be conducted with one drop of blood, urine or any other body fluid at phenomenally low costs”, Dr. Chakraborty added.

The team also included Naresh Mani, a visiting scholar from Manipal Institute of Technology and Sujay Kumar Viswas, a Ph.D student at IIT Kharagpur. The research results have been published in journal Scientific Reports.

Image and news credit: India Science Wire , written by Sunderarajan Padmanabhan